When consumers purchase medications for their health conditions, they do so with the expectation that manufacturers have produced these drugs with techniques that preserve their integrity and make them safe for consumption. One process that helps them meet that expectation is lyophilization. Read below to understand the role of lyophilization in pharmaceuticals and how it can help your company produce effective drugs with a longer shelf life.

How Lyophilization Works

Lyophilization, also known as freeze-drying, is a complex but highly efficient process that involves removing water from a pharmaceutical substance by freezing it. This method is highly favorable for preserving sensitive materials that otherwise degrade when exposed to liquid water.

Why Pharmaceutical Companies Use Lyophilization

Lyophilization offers many benefits to pharmaceutical companies, including the ability to extend a drug’s expiration date. The process can also help maintain the integrity of pharmaceutical products and prevent them from being contaminated. The technology is exceptionally effective with vaccines.

The process can also help pharmaceutical companies streamline their processes by significantly reducing the amount of labor associated with shipping and handling drugs. This efficiency lessens the burden on supply chain logistics by making products shelf-stable and diminishing the need to keep them refrigerated.

Lyophilization also allows these vital medications to get to market more quickly, which makes it a cost-effective solution for pharmaceutical operations. In short, lyophilization is a critical tool in the pharmaceutical industry, enhancing the practicality, efficacy, and accessibility of modern medications on a global scale.

The Stages of the Lyophilization Process

Now that you understand the role of lyophilization in pharmaceuticals, it is important to explain what happens during the process. This procedure can be separated into three fundamental stages. Each one is crucial for ensuring the quality and stability of the final pharmaceutical product.

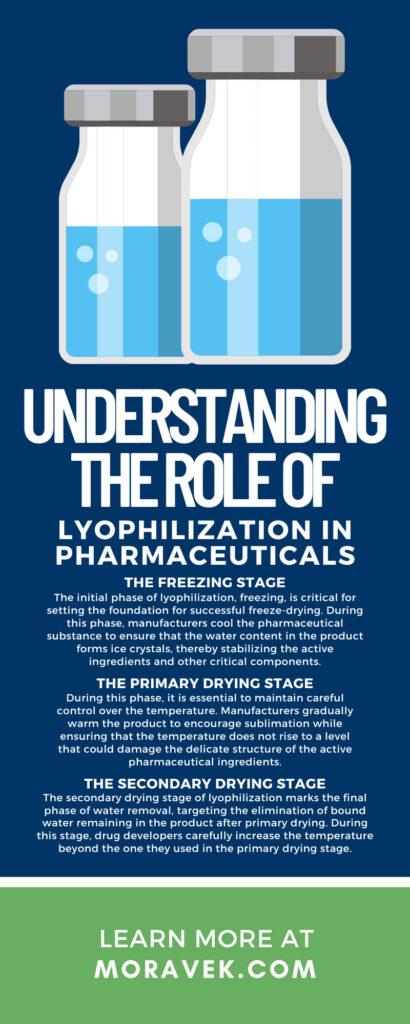

The Freezing Stage

The initial phase of lyophilization, freezing, is critical for setting the foundation for successful freeze-drying. During this phase, manufacturers cool the pharmaceutical substance to ensure that the water content in the product forms ice crystals, thereby stabilizing the active ingredients and other critical components.

However, there is a danger that large crystals can puncture and disrupt the delicate structure of the product, potentially compromising its integrity and efficacy. Therefore, the method of freezing—whether it involves using liquid nitrogen, a controlled-rate freezer, or immersion in a chilled bath—plays a significant role in determining how big the ice crystals may grow, which has a direct influence on the quality and stability of the final lyophilized product.

The Primary Drying Stage

During the primary drying phase, manufacturers will remove most of the water from their pharmaceutical products. Through the process of sublimation, they dry the frozen product, transition the ice into vapor, and collect it with a condenser.

During this phase, it is essential to maintain careful control over the temperature. Manufacturers gradually warm the product to encourage sublimation while ensuring that the temperature does not rise to a level that could damage the delicate structure of the active pharmaceutical ingredients.

The Secondary Drying Stage

The secondary drying stage of lyophilization marks the final phase of water removal, targeting the elimination of bound water remaining in the product after primary drying. During this stage, drug developers carefully increase the temperature beyond the one they used in the primary drying stage. However, it is still critical to keep the temperature below one that could cause a critical collapse in the product to avoid compromising its structural integrity.

The increase in temperature allows for the desorption of bound water molecules from the product, effectively reducing the moisture content to levels that ensure the stability and longevity of the pharmaceutical compound. This stage is critical for achieving the optimal residual moisture content that satisfies both the physical stability of the product and its efficacy upon reconstitution.

What You Need To Perform Lyophilization

After reviewing the lyophilization process, you may be considering utilizing it in your drug manufacturing operations, so you must understand what you will need to complete it successfully. For example, the core apparatus in a lyophilization system is the lyophilizer or freeze dryer, which manufacturers build to manage the freezing, primary drying, and secondary drying stages under controlled conditions.

Additionally, temperature and pressure monitoring devices are indispensable for the successful execution of the lyophilization process. These instruments ensure that the product undergoes freeze-drying under optimal conditions, preventing product degradation or suboptimal drying. Advanced lyophilizers also integrate computer-controlled systems that allow for the precise programming of cooling and heating cycles, adapting to the specific thermal characteristics of each pharmaceutical product.

Preparing a product for lyophilization also involves the use of high-quality, sterile vials or other suitable containers that can withstand the low temperatures and vacuum conditions without compromising the product's sterility or the container's integrity. The choice of closure systems is also crucial in maintaining the sterility and stability of the product post-lyophilization.

Lastly, the successful implementation of lyophilization demands skilled personnel with a deep understanding of the process's dynamics and the ability to interpret temperature, pressure, and moisture data. This expertise will allow them to make informed adjustments throughout the drying stages. Continual research into materials science, thermodynamics, and pharmaceutical formulation further supports the development of optimized lyophilization protocols, contributing to the advancement of drug manufacturing and preservation techniques.

What the Future Holds for Lyophilization

Looking ahead, lyophilization appears to have a strong future in the pharmaceutical industry. As manufacturers develop more products, their need for this process will continue to grow. Likewise, the technology that drug developers use for lyophilization will also evolve.

Automation may soon further advance this procedure, while analytics will provide deeper insights into freeze-drying. These advancements will enable manufacturers to monitor the critical parameters more accurately, ensuring the consistency and efficacy of lyophilized products. In essence, the evolution of lyophilization technology stands to bolster the pharmaceutical industry’s capabilities significantly, enhancing global health outcomes through more stable, effective, and accessible medications.

As we’ve seen, the use of lyophilization is critical in pharmaceutical processing, enabling the stabilization and distribution of complex pharmaceuticals worldwide. Moravek can help you in the development of pharmaceuticals with our custom radiolabeling services. We can manufacture carbon-14- and tritium-labeled compounds that are specifically tailored to the needs of your research or clinical trials.