Reliability and consistency are key in pharmaceutical development. However, issues can arise, affecting medications and clinical trials. Learn more about some common API mistakes and how to avoid them with this comprehensive guide.

API Manufacturing

An active pharmaceutical ingredient (API) is the active component of a specific medicine, and it acts as a medicinal application agent. Pharmaceutical products contain inactive excipients that deliver medicine to target systems and the APIs themselves.

Please note that APIs aren’t pure, unfiltered drugs. Scientists must properly process APIs to develop safe medicine for clinical purposes. APIs are not raw materials; rather, compounds are created through chemical combinations.

Production Characteristics

API manufacturing includes intricate chemical processes. The synthesis of APIs from raw materials requires multi-step procedures that use high-tech processing technologies. These steps include selecting a compound structure, generating a high quantity of the API, and analyzing the compound for quality control and assurance.

API manufacturers have set standards to determine the strength and size of an API in each medication. However, standards vary from brand to brand due to differences in testing methods and potencies. Given the volatile nature of the products, quality API production requires exceptional expertise, efficiency, and concentration.

API manufacturing must meet stringent quality regulations. The quality of APIs correlates to the effectiveness of desired results and the safety of medications. Bad or compromised APIs are unusable in pharmaceuticals. That said, scientists must follow precise steps in accordance with Good Manufacturing Practice (GMP) requirements to meet FDA regulations.

Challenges in Drug Manufacturing

Drug manufacturing is a time-consuming process that virtually requires perfection; there is no room for errors or hiccups. Any problems that arise throughout the API development process must be carefully analyzed, regardless of being a major or minor issue.

Even the smallest issue has the potential to obstruct development and may affect the chances of a medication being introduced to the market. Therefore, it’s worth assessing potential problems before they get out of control.

Potency and toxicity are significant elements in drug manufacturing. It’s essential to recognize that these terms aren’t the same thing. According to Highly Potent APIs—Markets, Myths, and Manufacturing, “some highly potent molecules have a pharmacological effect at a very low dose but toxic effects do not kick in until the administered dose is much higher.”

Drug manufacturers must monitor all aspects of medicines to understand minimum and maximum dosages, side effects, and drug specifications. Determining what makes a medication safe and effective is a tough but necessary job.

FDA Compliance

In general, the FDA requires data that supports and verifies the identity, strength, quality, purity, and potency of substances and drug products. Any documentation regarding a medicine must be reproducible.

The FDA provides clear guidelines for method validation requirements. Under these guidelines, equipment and procedures must be based on the analytical method. Evaluating factors include specificity, precision, accuracy, linearity, limits of detection (LOD) and limits of quantitation (LOQ), and range.

During the early stages of method development, procedures should be evaluated to help Contract Manufacturing Organizations (CMOs) and other scientists decide which methods they’ll submit to the FDA for approval. All this to say, the FDA wants clear, concise data regarding drugs.

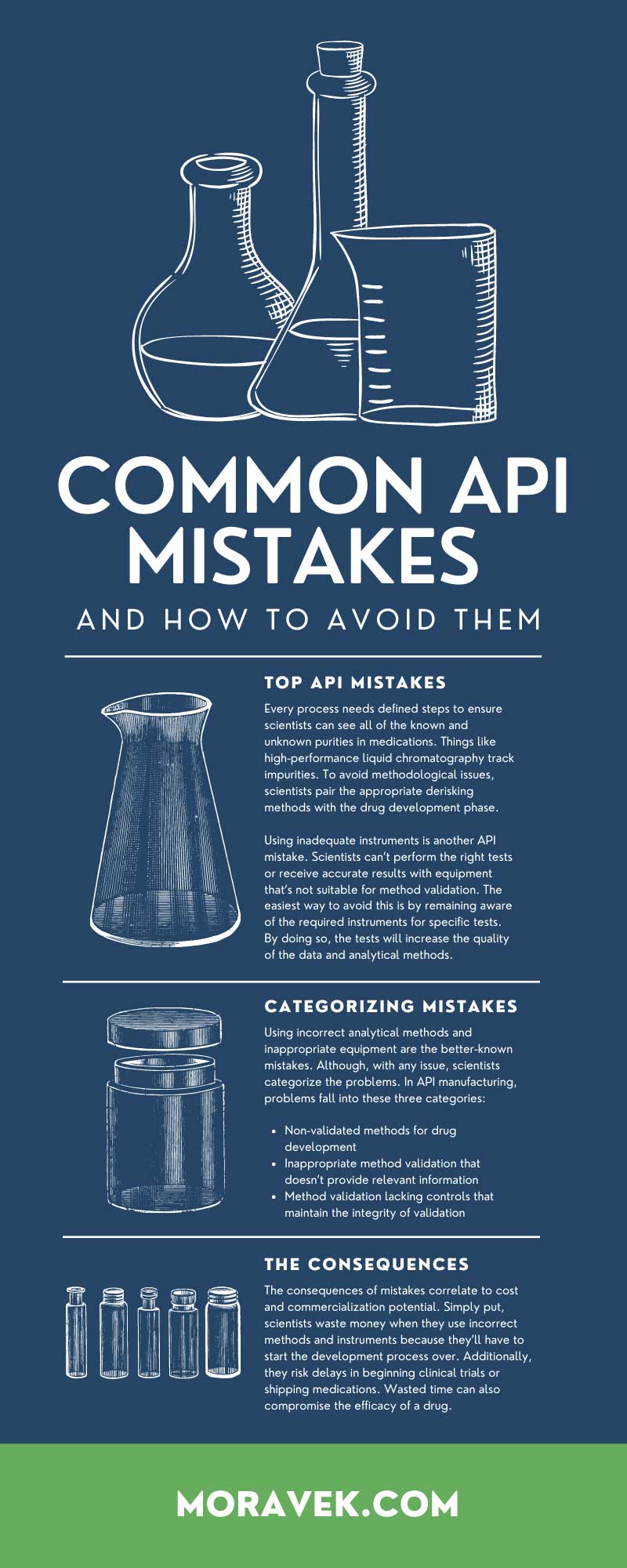

Top API Mistakes

API manufacturing and strategy development come with their own set of risks. That said, one common API mistake to avoid is suggesting an inappropriate analytical method. The wrong methodology is a surefire way to fail.

Every process needs defined steps to ensure scientists can see all of the known and unknown purities in medications. Things like high-performance liquid chromatography track impurities. Toavoid methodological issues, scientists pair the appropriate derisking methods with the drug development phase.

Using inadequate instruments is another API mistake. Scientists can’t perform the right tests or receive accurate results with equipment that’s not suitable for method validation. The easiest way to avoid this is by remaining aware of the required instruments for specific tests. By doing so, the tests will increase the quality of the data and analytical methods.

Categorizing Mistakes

Using incorrect analytical methods and inappropriate equipment are the better-known mistakes. Although, with any issue, scientists categorize the problems. In API manufacturing, problems fall into these three categories:

- Non-validated methods for drug development

- Inappropriate method validation that doesn’t provide relevant information

- Method validation lacking controls that maintain the integrity of validation

The Consequences

The consequences of mistakes correlate to cost and commercialization potential. Simply put, scientists waste money when they use incorrect methods and instruments because they’ll have to start the development process over. Additionally, they risk delays in beginning clinical trials or shipping medications. Wasted time can also compromise the efficacy of a drug.

Reasons Behind Method Validation Problems

At times, validation problems are present before studies even begin. The root cause of these issues is a lack of understanding of molecule properties. Scientists need to understand the physiochemical properties, like the molecule’s reactivity, pH level, melting point, boiling point, and light sensitivity.

Understanding these properties prevents incorrect studies. For example, if a molecule is moisture-sensitive, it’s clear that scientists shouldn’t expose it to water. Without this knowledge, professionals risk compromising APIs.

Besides failing to assess physiochemical properties, scientists may fail to follow a precise questionnaire, consider future testing, or optimize methods.

Ignoring the 10 Questions

Before creating an analytical method for a product’s intended use, some scientists forget to make a method validation plan. The plan must address the following key questions:

- Is this method for the release of raw material?

- Is this method for in-process control?

- Is this method for final product release testing?

- What is the route of administration for this product?

- What is the maximum daily dose for this product?

- How long does the drug product’s administration take?

- What are the crucial components that need to be monitored for each sample of the product?

- What are the specifications?

- Does the compound have any genotoxic impurities?

- What is the impurity profile?

Not Considering Future Method Testing

From the beginning, it’s crucial to prepare for reviews of all analytical methods pertaining to APIs. Expect a peer review of methodologies, a quality assurance review, and a regulatory review. This ensures that scientists can validate procedures at each progressive step. If needed, professionals will document changes before moving to the next step.

Failing To Incorporate Method Optimization

Scientists should incorporate method optimization when studies look promising for APIs. This initiative includes improving method specificity, studying stability, and monitoring sensitivity. Ultimately, drug development will progress, and optimized methodology will increase efficiency.

How To Avoid Mistakes

The best way drug developers overcome API worries is by outsourcing their API strategies. Utilizing API manufacturing services increases accuracy and efficiency. At Moravek, we have prepared over 70 14C APIs for use in clinical trials worldwide. All of our materials are supplied on time with extensive documentation, and they meet all regulatory requirements.