Moravek offers custom GMP manufacturing of carbon-14 labeled active pharmaceutical ingredients (APIs) suitable for use in Phase 0 and Phase 1 clinical trials.

Compliance, Certification, and Facilities

Regulatory agencies including the U.S. Food and Drug Administration have adopted ICH Q7 Section 19 as appropriate guidance for the manufacture of APIs suitable for use in early phase clinical trials. Moravek’s GMP services, such as radiosynthesis, purification, dilution with non-labeled GMP API, and analysis, are performed in compliance with this guidance. GMP manufacturing and related services are carried out under a Drug Manufacturing License from the California Department of Public Health - Food and Drug Branch that was issued after an audit of our Quality System.

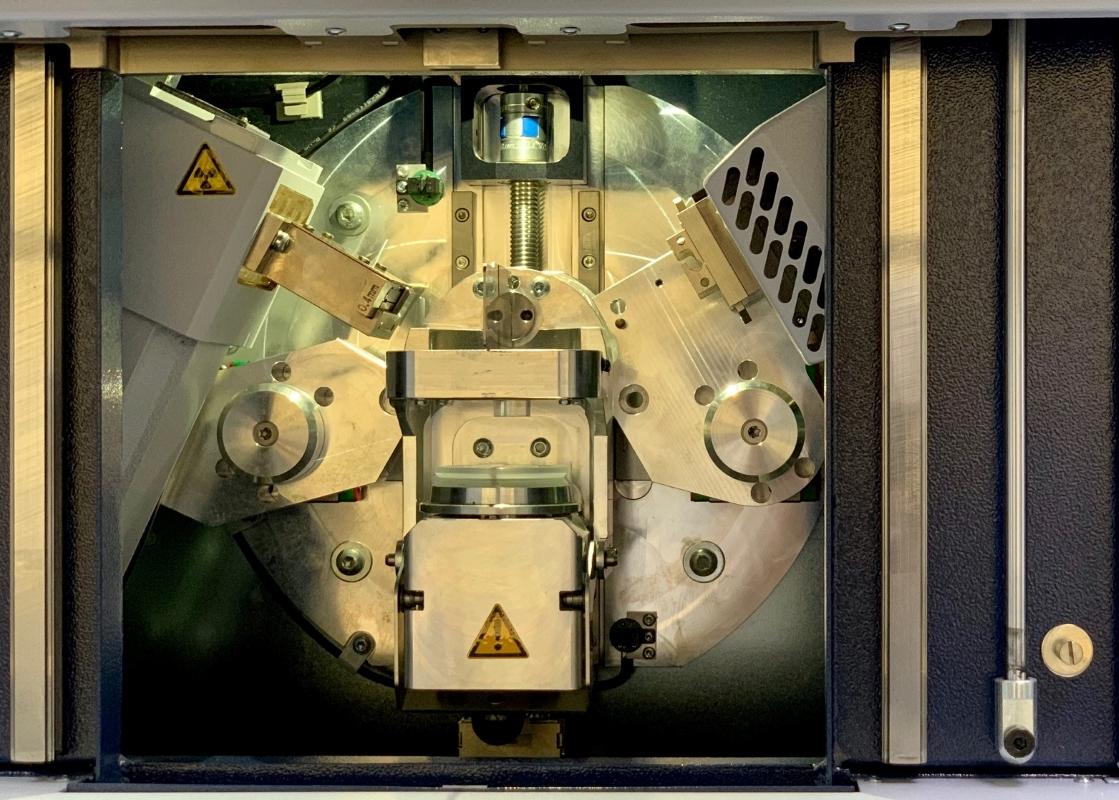

Analytical data for GMP campaigns, generated using Agilent, Rees Scientific, Thermo Fisher, and Mettler Toledo equipment, is stored using 21 CFR Part 11 compliant data solutions, such as Agilent’s Enterprise Content Management System and Rees Scientific’s Environmental Monitoring System. These data integrity compliance solutions are present throughout our state-of-the-art facilities, including our four ISO Class 7 cleanrooms and our well-equipped Quality Control laboratory.

Experience

Our team has successfully manufactured over one hundred GMP 14C-labeled APIs for use in clinical trials, all of which have been supplied with extensive documentation and have met all client, contract research organization, and regulatory requirements. Our GMP services are governed by our Quality System, which continues to undergo refinement as a result of feedback we receive from Quality Assurance audits by our valued clients, including some of the world’s leading pharmaceutical companies. Moravek also performs annual internal audits to ensure that our Quality System is GMP-compliant. Our expertise in radiolabeling and strong focus on quality contribute to our exceptional track record.

Standard GMP Services

Working With Moravek

Initiation Of Discussion With Moravek

We would be glad to evaluate your team’s project needs and/or discuss any questions regarding our GMP capabilities and facilities. Please contact our team to discuss your project with one of our Proposal Development Coordinators.

Proposal Generation

Our radiochemistry specialists and Proposal Development Coordinators will work with you to design an efficient GMP 14C-labeled API manufacturing campaign with a scope of work that meets regulatory requirements. We routinely review crucial elements of the campaign, such as selection of label position, timing requirements, and release testing specifications to help ensure that the campaign is tailored to meet your team’s needs and expectations.

Quality Assurance Audits

We welcome our clients to carry out an audit of our Quality System and facilities. Our Quality Assurance Department routinely hosts in-person and remote audits by our clients.

During the GMP Manufacturing Campaign

A dedicated Project Manager will work with your team to provide comprehensive project coordination and logistics support to facilitate a successful campaign. In addition, we can communicate and coordinate directly with your team’s CRO throughout the campaign to align each team’s expectations regarding project details such as deliverables, documentation, and timelines.