Radiolabeled compounds rely on the use of radioactive isotopes (also referred to as radioisotopes) for enrichment. Since radiation is historically bad for human beings, extra care must be taken to ensure that no harm comes to either the people involved in developing these radiochemicals or the compounds themselves; after all, if improper handling procedures were common in this country, the U.S. would not be the number one largest national producer of chemical products globally.

The care and storage of these radioisotopes require laboratory personnel to follow special rules known as good manufacturing procedures (GMP). When it comes to GMP storage (such as that involved in carbon 14 production) these rules are connected both to the staff and the laboratory itself.

Safety First

Radioisotope laboratories are classified (in some countries) into A, B, and C categories depending on the risk of incorporation -- this refers to the radioactive damage exposure could cause. Category A refers to a facility that handles a large quantity of activity, which requires the use of a safety interlock system, surveillance equipment, and radiation monitoring.

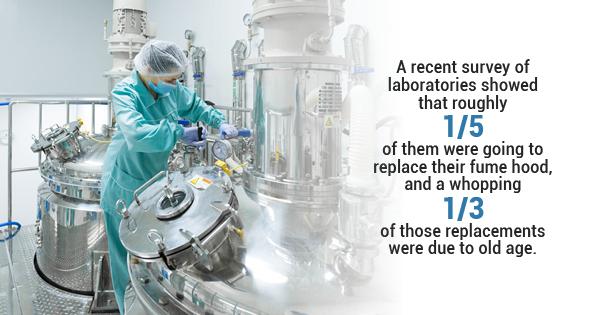

Once access control is safely established to prevent those unauthorized from gaining entrance to such a risky environment, the basis of contamination control falls on a well-planned ventilation system. Fume hoods filter the air that is supplied and exhausted from the lab; a recent survey revealed that one-fifth of laboratory fume hoods need to be replaced, so ensuring that your system is capable of handling the work involved in air filtration is crucial to GMP storage.

Location And Storage

Most radioisotope handling and processing centers are a considerable distance away from big cities and industrial areas; though this means the air will be cleaner than in a city center, it's important to cover the possibility of failure with a warning system. In terms of physical GMP storage, radioactive materials require an exhausted and shielded special enclosure called a hot cell. Though these materials are typically manufactured in small batches using small quantities of materials, heavy lead containers are also used for protection from radiation.

When it comes to the storage and care of radiolabeled compounds and radioactive isotopes, it is always better to be safe than sorry!